Technical

Recommendations

Views: 2498

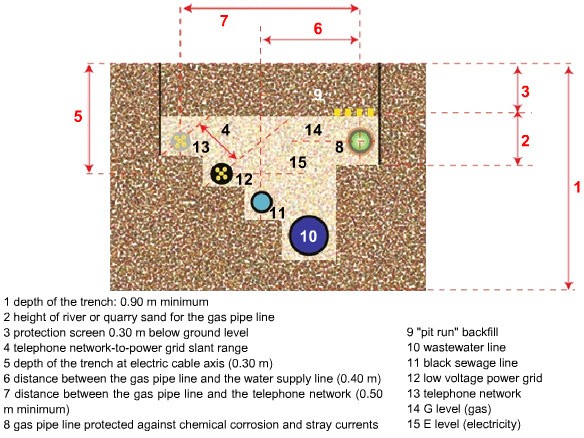

The tubes are placed end-to-end above the trench on supports before assembly by welding. Once the pipe lines have been welded, they must undergo a hydrostatic mechanical

resistance test at 1.5 times maximum pressure, using water, and then be emptied of their water content using compressed air to eliminate dust, sand and any other scale found in the tube.

Next, a leak test must be performed at working pressure.

WP: for HDPE pipe lines, the mechanical resistance test will be performed at 10 bars.

All sections of the tubes that have not been insulated (location of solders and connections)

against corrosion must be, using the same insulation as that of the tube.

All protective insulation must be inspected. If a section of insulation has deteriorated, it must be repaired.