Technical

“Small bulk” from 250 kg to 2 tons

Views: 3359

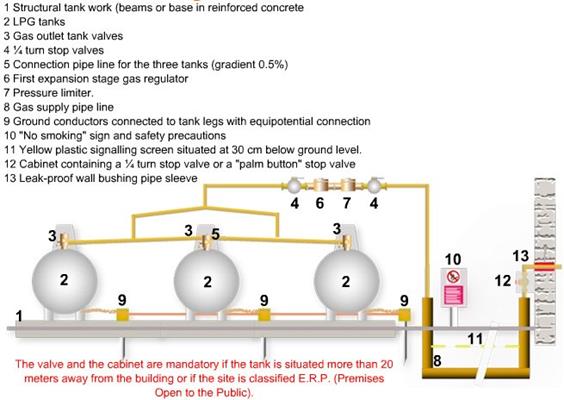

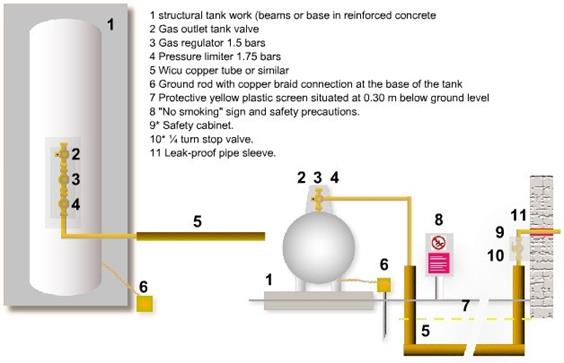

An LPG tank is equipped with its safety and operating components as well as a ground conductor.

After the tank gas outlet valve:

1 pressure reducing outlet valve of 1 .5 bars

1 pressure limiter, outlet pressure of 1 .75 bars

X meters of copper pipe line, diameter according to flow rate.

3MCO recommendations or IGU** specifications: B 524-1

If a section of this pipe line must be buried, provide for a 0.60 m deep trench and a yellow plastic screen situated 30 cm below ground level (see trenches file).

This buried pipe line will be treated against corrosion and stray currents (wicu copper tube or similar).

The gas regulator outlet pressure of 1.5 bars can be set to 1 bar or less, which makes it possible to increase the natural vaporisation rate of the tank or tanks.

Before building entry, provide a general stop valve housed in a case.

For the E.R.P. (Premises Open to the Public) provide a general “palm button” emergency shutdown valve housed in a case outside the building.

Note: If the tank is able to be accessed by the public, provide a chain-link fence and place a “no smoking” sign on each side of the fence together with safety precautions on the front gate of the storage area.

• ** IGU: International Gas Union

Standard dimensions of “small bulk” tanks from 250 kg to 2,000 kg

.jpg)

1 above-ground tank

The valve and the cabinet are mandatory if the tank is situated more than 20 meters away from the building or if the site is classified E.R.P. (Premises Open to the Public).

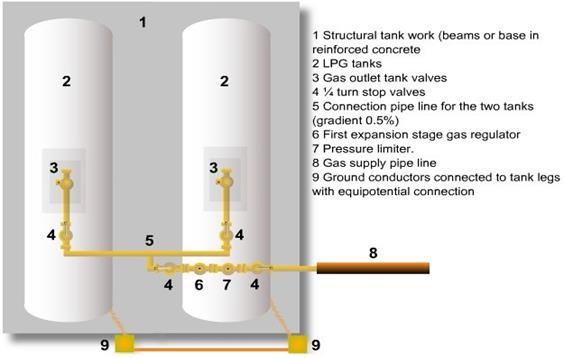

2 above-groud tanks “top view”

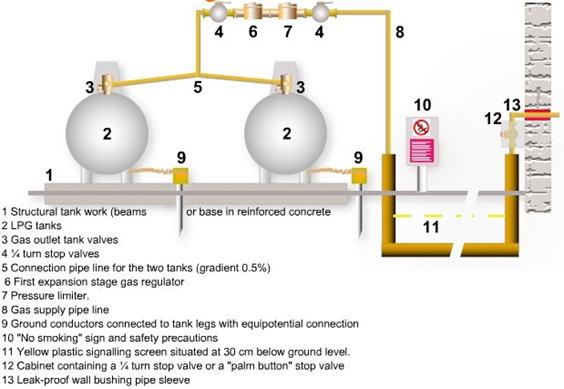

2 above-ground tanks “side view”

The valve and the cabinet are mandatory if the tank is situated more than 20 meters away from the building or if the site is classified E.R.P. (Premises Open to the Public).

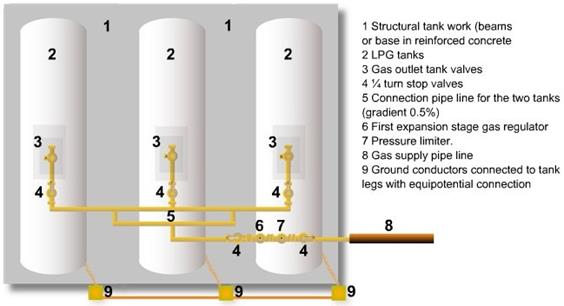

3 above-ground tanks “top view”

3 above-ground tanks “side view”